スチレン系特殊透明樹脂(SBC)アサフレックス®

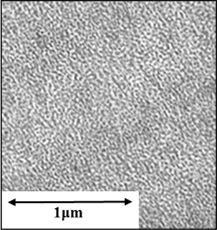

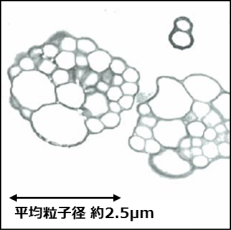

アサフレックス®は、優れた透明性と柔軟性、ヒンジ性を兼ね備えたスチレン・ブタジエン共重合樹脂(SBC)です。ブタジエンゴム成分(ゴム相)が可視光の波長よりも微細に分散している為、高い透明性を維持しながら、柔軟性・ヒンジ性を有しております。

アサフレックス®

(透明)

耐衝撃性ポリスチレン(HIPS)

(乳白色)

GPPSなどのスチレン系樹脂との相容性が良好で、任意の比率でブレンドが可能です。

| 製品銘柄 | MFR*1 | 曲げ弾性率 | ビカット軟化温度*2 | 曇価*3 | 用途 |

|---|---|---|---|---|---|

| 800S | 6 | 2250 | 96 | 3.0 | 食品容器 医療関連部材 透明成形品 |

| 805 | 10 | 1550 | 91 | 0.5 | 食品容器 医療関連部材 透明成形品 |

| 810 | 5 | 1400 | 83 | 1.2 | 樹脂改質 接着剤・シーラント フットウェア 透明成形品 |

| 815 | 6 | 1200 | 82 | 0.5 | 食品容器 樹脂改質 |

| 825 | 6 | 1200 | 82 | 0.5 | 樹脂改質 フットウェア 透明成形品 |

| 830 | 6 | 1100 | 72 | 2.0 | 樹脂改質 透明成形品 |

| 835 | 6 | 1100 | 72 | 2.0 | 食品容器 樹脂改質 |

| 840 | 7 | 1500 | 81 | 1.2 | 樹脂改質 透明成形品 |

| 845 | 7 | 1500 | 81 | 1.2 | 食品容器 樹脂改質 |

*1 200°C, 5kgf

*2 荷重=10N、50K/h

*3 透明性 : 2mm板

アサフレックス®の特長

- 高い透明性と優美な光沢を有しています。

- 低温衝撃性に優れます。

- スチレン系樹脂との相容性に優れます。

- GPPSに柔軟性を付与します。

- ヒンジ特性に優れています。

- インフレーション成形等、幅広い成形加工法を使用出来ます。

- ガンマ線による滅菌用途に使用可能です。

- アクリル並みの低複屈折を有しています。

- 着色・印刷が可能です。

アサフレックス®の代表用途

一般のスチレン系樹脂同様、射出、押出、インフレーションなどの成型加工が可能です。また、フィルムの延伸性も優れ、シュリンクフィルムとしても好適に使用頂けます。

- 高い透明性、優美な光沢と印刷性や低温収縮性を活かしたフィルム

シュリンクフィルムなど - 容器及び包装材料

食品容器、飲料カップ・蓋、かき氷・アイスクリーム容器、ブリスターパッケージなど - 透明ケース及び部品

ヘアスプレーキャップ、目薬容器など - 玩具

プラモデル、ガラガラ、ミニカー、輪投げなど - 医療用機器、及びにその包装材

試験管、排尿容器 、シャーレ、点滴筒など

アサフレックス®ブレンドシミュレーション

アサフレックス®とGPPSまたはMS樹脂*1)とのブレンドシート物性(透明性および耐衝撃性)を推定できます。

アサフレックス®の配合量(wt%)をご入力ください。

各データをご使用頂く前にご確認下さい

掲載分以外の技術データも各種取り揃えております。

お気軽に弊社までお問い合わせください。 製品のお取扱いに際しては、必ず事前に各製品の安全データベース(SDS)をご確認下さい。

本サイトの活用の前に、必ず「本サイトのご利用にあたってのご注意(Terms)」および「プライバシーポリシー(Privacy)」をご覧下さい。

また工業所有権にも十分にご注意ください。 なお掲載している各データや特徴は一般的なものであり、その内容を保証するものではございません。製品のお取扱いに際しては、用いる用途に関する法令、規格及び使用制限等への適合性、並びにかかる用途の要求特性に対する適合性及び安全性の確認を実施頂きますようお願いします。

医療用途に関する注意事項

弊社製品を医療機器向け素材、または食品・医薬品用途向け素材(容器・包材含む)に使用される際には、必ず事前に弊社にご連絡頂き、その使用条件等をご確認下さい。その際には最終用途を確認させて頂きますが、用途によっては使用をお断りする場合もございますので、その旨ご了解下さいますようお願い致します。 適合法規等には、2015年1月時点での代表的な適合法規を掲載しておりますが、最新状況については必ず弊社までご確認下さいますようお願いします。