Hydrogenated Styrenic Thermoplastic Eastomer (SEBS) Tuftec™ H1062

Applications

Physical Form

- Supplied as a dusted, dence pellet 2 types of dusting agenst

Features and Benefits

- Good mechanical property at low temperature

- Excellent impact modifier for PP

- Good transparency

- Strong heat seal property

Regulations

- FDA 21 CFR FCN821

- Regulation (EU) No 10/2011

Characteristics

| Property | Test Method | Unit | Value |

|---|---|---|---|

| Specific Gravity | ISO 1183 | g/cm3 | 0.89 |

| MFR 230°C, 2.16kg Load | ISO 1133 | g/10 min | 4.5 |

| Hardness Durometer Type A |

ISO 7619 | °Shore A | 67 |

| Tensile Strength Dumbbell: Type 1A 500 mm/min |

ISO 37 | MPa | 15.0 |

| Elongation Dumbbell: Type 1A 500 mm/min |

ISO 37 | % | 670 |

| 300% Tensile Stress | ISO 37 | MPa | 4.3 |

| Styrene / Ethylene-Butylene Ratio | Asahi Kasei Method | – | 18/82 |

Please note that all data and values are given as typical results obtained with the indicated test methods for purposes of basic reference in grade selection only, and not as any product specification or warranty of any nature, and are subject to change without notice.

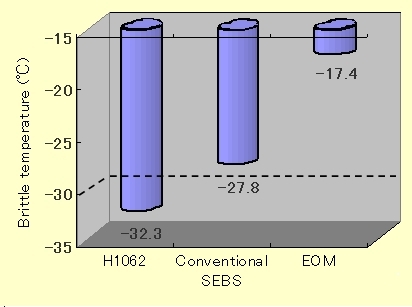

Typical characteristics of PP/H1062/talc and two other elastomer blends*

| Property | Test method | H1062 | Conventional SEBS | EOM |

|---|---|---|---|---|

| Styrene content (wt%) | Asahi Kasei method | 18 | 13.0 | – |

| MFR (g/10 min) 230°C, 2.16 kg load |

ASTM D 1238 | 17 | 19.9 | 15.6 |

| Rockwell hardness | ISO 2039-2 | 60 | 52 | 69 |

| Flexural modulus (MPa) | ASTM D 790 2mm/min |

1820 | 1820 | 2270 |

| Tensile strength (MPa) | ASTM D 638 20mm/min |

18.0 | 19.2 | 20.0 |

| Elongation (%) | 465 | 193 | 129 | |

| Izod impact strength (J/m) 1/8 inch notched, 23°C |

ASTM D 256 | 650 | 650 | 449 |

| Heat distortion temp. (°C) 0.45 MPa |

ASTM D 648 | 106.2 | 113.0 | 112.5 |

| Brittle temp. (°C) | ASTM D 746 | -32.3 | -27.8 | -17.4 |

EOM: ethylene-octene copolymer

* Formulations: PP block copolymer(MFR 30)/Tuftec™ H1062/talc, 65/15/20.

Compounding cylinder temp.: 210°C.

Molding conditions; Cylinder temp.: 230°C, Mold temp.: 40°C, Injection time: 10 sec, Cooling time: 30 sec.

Polypropylene block copolymer modified with Tuftec™ H1062 is superior in impact resistance, elongation, and low-temperature brittleness.

Formulations: PP block copolymer(MFR 30)/Tuftec™ H1062/talc, 65/15/20.

Compounding conditions

Compounding cylinder temp.: 210°C

Injection molding

Molding conditions; Cylinder temp.: 230°C, Mold temp.: 40°C, Injection time: 10 sec, Cooling time: 30 sec.

Please note that all data and values are given as typical results obtained with the indicated test methods for purposes of basic reference in grade selection only, and not as any product specification or warranty of any nature, and are subject to change without notice.

Please refer to Terms and Conditions and Privacy Policy

IMPORTANT NOTICE REGARDING MEDICAL APPLICATIONS

We, Asahi Kasei Group, request that customers who are considering using our products in medical, pharmaceutical, cosmetic and other related applications (hereinafter collectively called “Medical Applications”) shall contact us and confirm our policy on Medical Applications in advance. Information herein regarding conformity to certain laws and regulations are as of January, 2015. Please consult with us for the latest status. We make no guarantees or warranties, express or implied, concerning the suitability of our products for use in Medical Applications. It is not our responsibility to determine if our products are safe, lawful, and technically suitable for intended applications.